Arc flash and electrocution are common hazards workers are exposed to while working near energized electrical panels. The Electrical Safety Foundation International (ESFI) has reported over 2000 electrical workplace injuries and 126 fatalities due to electrical hazards in 2020. The number is way too high and raises some serious concerns: what causes these accidents? And, how can they be prevented?

OSHA requires employers to ensure electrical safety for their employees. OSHA Standard 1910.303 covers electrical installation practices that are critical to ensuring employee safety and maintaining equipment integrity. The standard also covers the requirement of appropriate markings to alert workers of potential electrical hazards and to keep the area in front of the equipment clear so that work can be performed safely.

What is the need for electrical panel clearance?

Electrical panels are potentially dangerous, any overlook can lead to serious accidents. Maintaining a clear area in front of the panels is necessary for several reasons -

- - Ensures safety of maintenance workers working around the panel

- - Ensures equipment safety

- - Keeps unaware people out of the restricted zone

- - Saves money spent on the repair of a damaged panel and downtime resulting from a potential power outage.

What are the official requirements for electrical panel clearance?

Section 1910.303(g)(1) of OSHA mentions how much access and working space is required around electric panels, operating at 600 volts or less to allow ready and safe working.

From the standard, it can be deduced that -

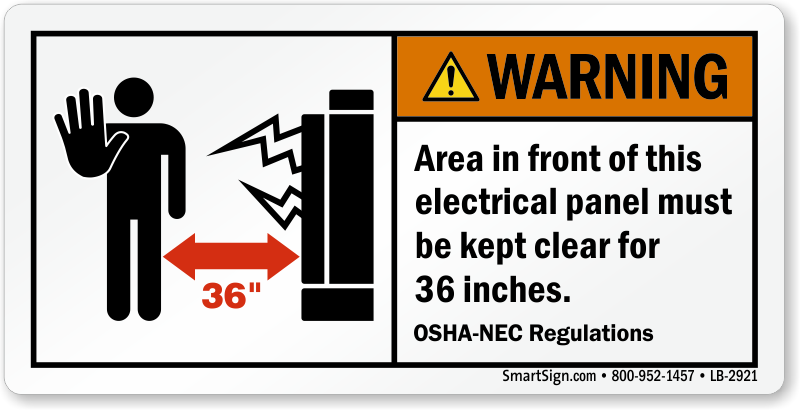

- - Electrical panels must have a minimum of 36 inches of clearance in front of the panel

- - A minimum clearance width of 30-inches or the width of the equipment, whichever is greater.

- - The clearance space must allow the electrical panel door to open at a 90-degree angle.

- - The vertical space from the floor to the ceiling around the electrical panel must be 78-inches in buildings built post-August 13th, 2007.

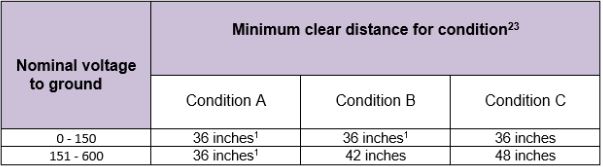

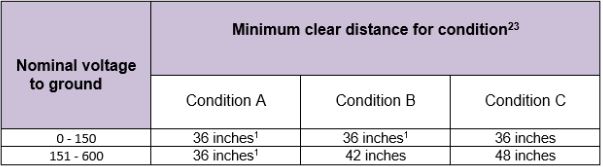

The following table states clearance details-

- 1. Minimum clear distances may be 30-inches for installations built before April 16, 1981.

- 2. Conditions A, B, and C are as follows:

Condition A—Exposed live parts on one side and no live or grounded parts on the other side of the working space, or exposed live parts on both sides effectively guarded by suitable wood or other insulating material. Insulated wire or insulated busbars operating at not over 300 volts are not considered live parts.

Condition B—Exposed live parts on one side and grounded parts like concrete, brick, or tile walls on the other side.

Condition C—Exposed live parts on both sides of the working space.

NFPA’s National Electric Code (NFPA 70 110.26) has the same clearance requirements for electrical panels.

How do signs and labels act as visual safety aids around electrical panels?

Sufficient and safe clearance around electrical panels can be maintained only via visual solutions and communication tools like signs, labels, and floor markings.

Signs:

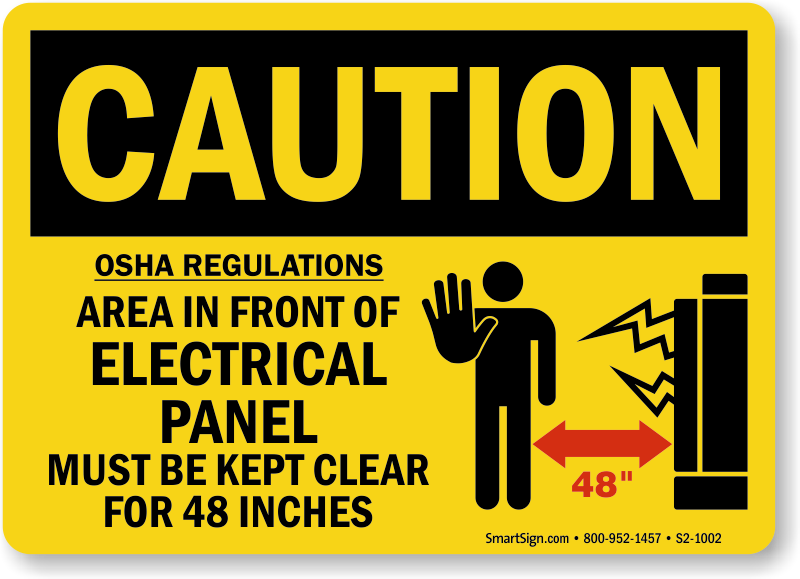

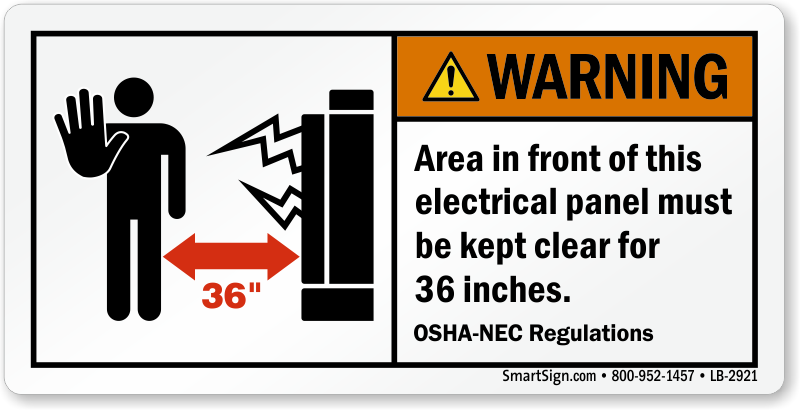

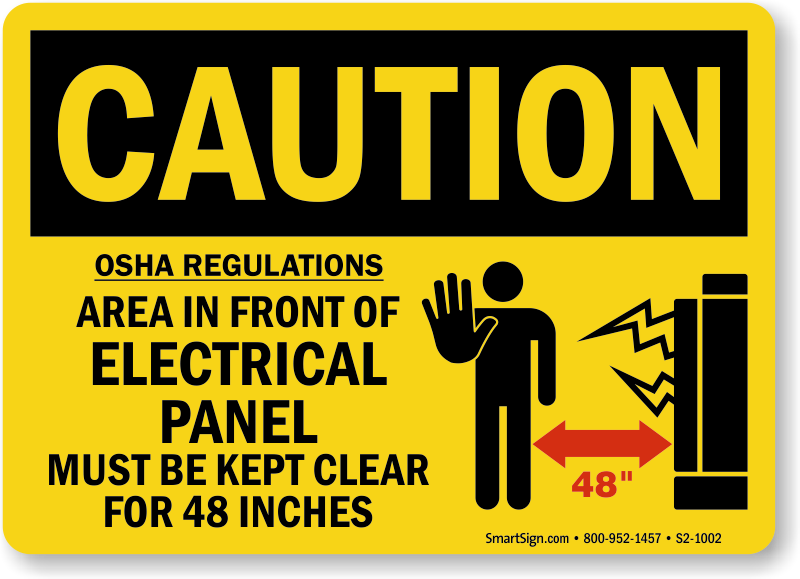

OSHA requires signs to be used “where necessary to warn employees about electrical hazards.” Both OSHA signs compliant with 29 CFR 1910.145 and ANSI Signs (a more up-to-date alternative to OSHA signage) can be used to convey the clearance details. Clearance signs help ensure that all workers, from electricians to janitors, obey the safe boundary.

Labels:

Electrical Panel Labels can be directly applied to the electrical panels, connected equipment, and the surrounding areas to prevent accidents like electric shock, burns, or failure of electric equipment parts. These labels typically include a word of warning, symbol, and safety message with a more detailed description. OSHA and ANSI prescribe red for Danger, yellow for Caution, and orange for Warning signs to grab attention.

Apart from the clearance warning near panels, other electrical components that must be labeled are:

- - Terminal blocks

- - Emergency system boxes and enclosures

- - Disconnect switches

- - Enclosed circuit breakers

- - Push-button stations

- - Battery racks

- - Power transfer equipment

- - Contractors (relays)

How can floor tapes be efficiently used to demarcate electrical panels safely?

Floor markings like floor tapes and adhesive floor signs demarcate the clearance area in front of electrical panels and state that the area in front of an electrical panel must be “kept clear”.

Floor Signs are easily distinguishable and provide clear information on instructions to be followed, leaving no room for ambiguity.

Floor tapes can outline the area to provide clear visual borders around circuit breaker panels and electrical boxes. Striped yellow-black or red-white tapes are some preferred options as they are bright and easy to spot. A simple ‘Keep Area Clear’ tape or a reflective tape, for low light conditions, works extremely well.

This Floor Marking Kit with pieces having puzzle-cut corners can be combined to use both as floor signs and tape to ensure workers have a visual barrier in front of the electrical panel.

Both tapes and signs are affordable and hard to miss. Markings make the hazard obvious and don’t let your employees become victims of electrical hazards. Sometimes, workers may rely on experience and luck - this can prove dangerous. Using appropriate marking tools is a way to discourage unsafe practices and tell your workers to identify possible electrical hazards.

What is the fine for not maintaining the required electrical panel clearance?

For serious, other-than-serious, and posting requirement violations, OSHA issues a fine amount of $14,502 per violation. Not posting required clearances in electrical panel areas, generally falls under this type of violation.

For failure to abate violations, the penalty amount is $14,502 per day beyond the abatement date.

And for willful or repeated violations, OSHA charges a massive $145,027 per violation.

*All data as per 2022 records.

Posting necessary Electrical Panel Clearance Signage saves employers from these hefty OSHA fines as well as prevents your workers from sustaining serious injuries or even death.